Suia

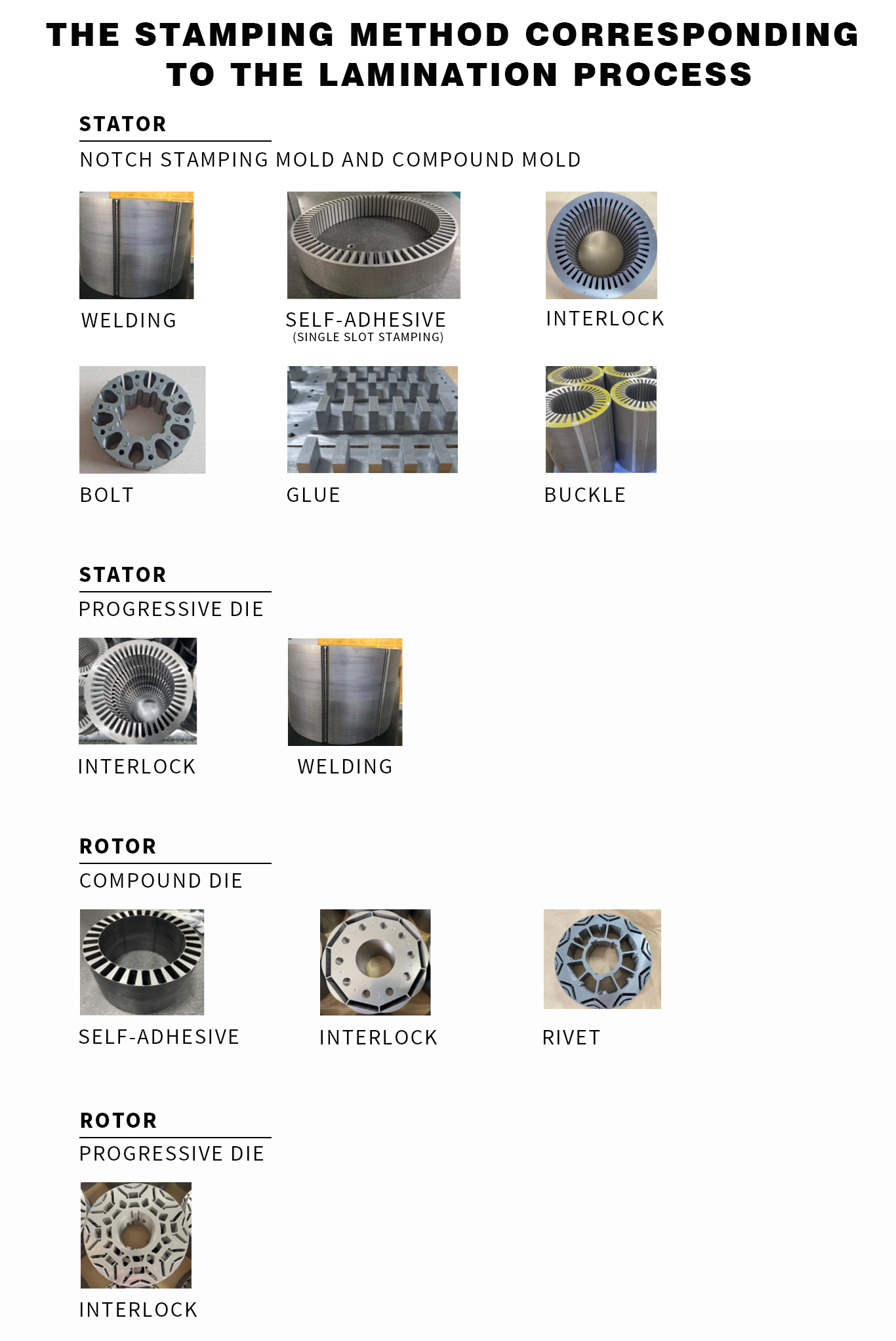

E i ai ni o matou e toʻatasi-slot punching, corlund punching, ma maualuga-saoasaoa punching e fetaui lelei e faʻafetaiaʻia manaʻoga o tagata eseese afi ma rotors. E uiga i le 90% o matouafi afi e masani ai mai ata. I le taimi o faʻataʻitaʻiga faʻataʻitaʻiga, o matou tagata tomai faʻapitoa o le a faʻavasega atu ni fautuaga lelei e sili atu le faʻamalieina o taumafaiga e sili atu le faamalieina.

Faʻataʻitaʻiga e faia

E mafai ona tatou fetaiaʻi ma le lautele ma tekonolosi o faʻataʻitaʻiga o le afi o loʻo manaʻomia.

A

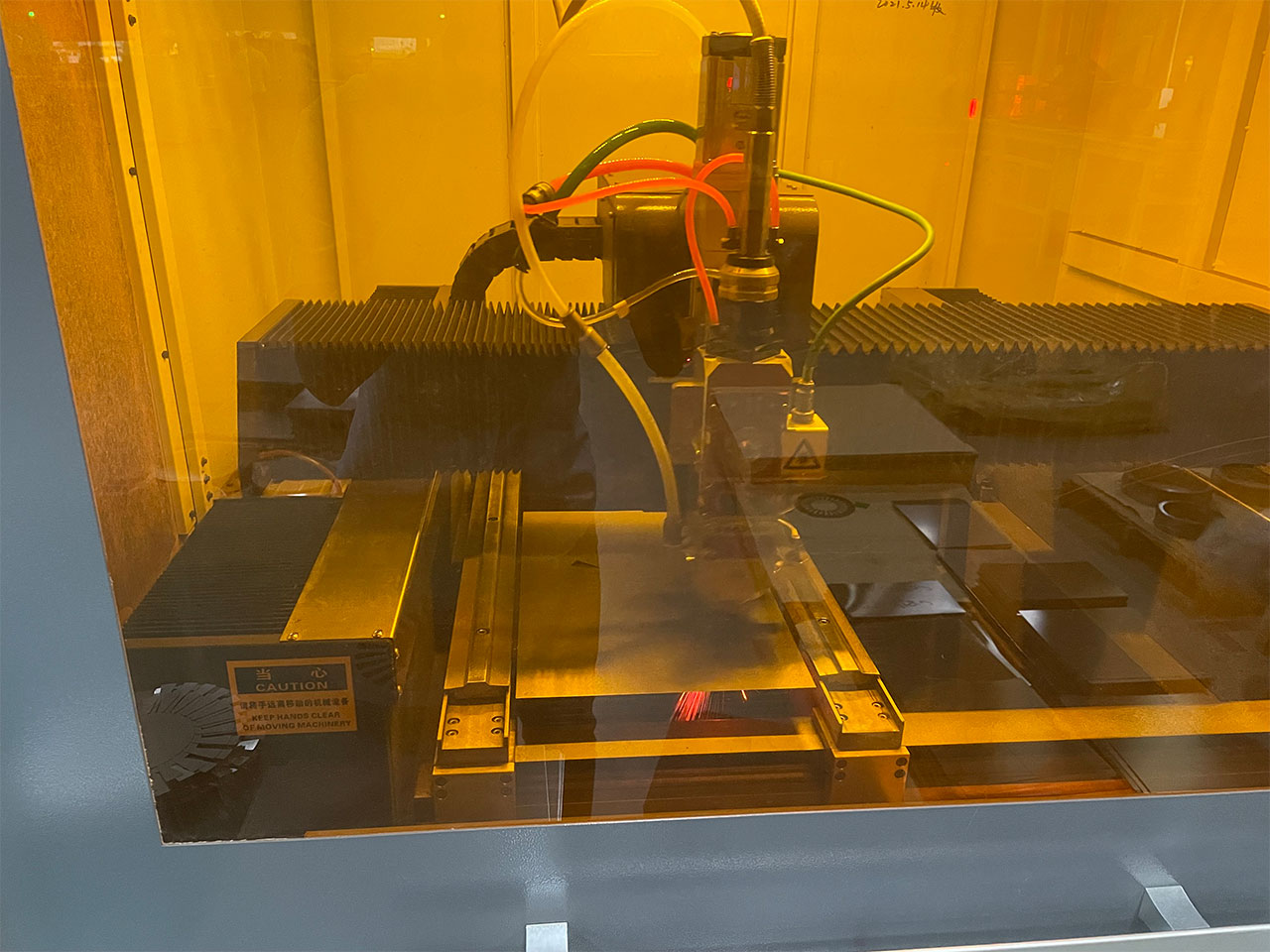

Laser tipi

C

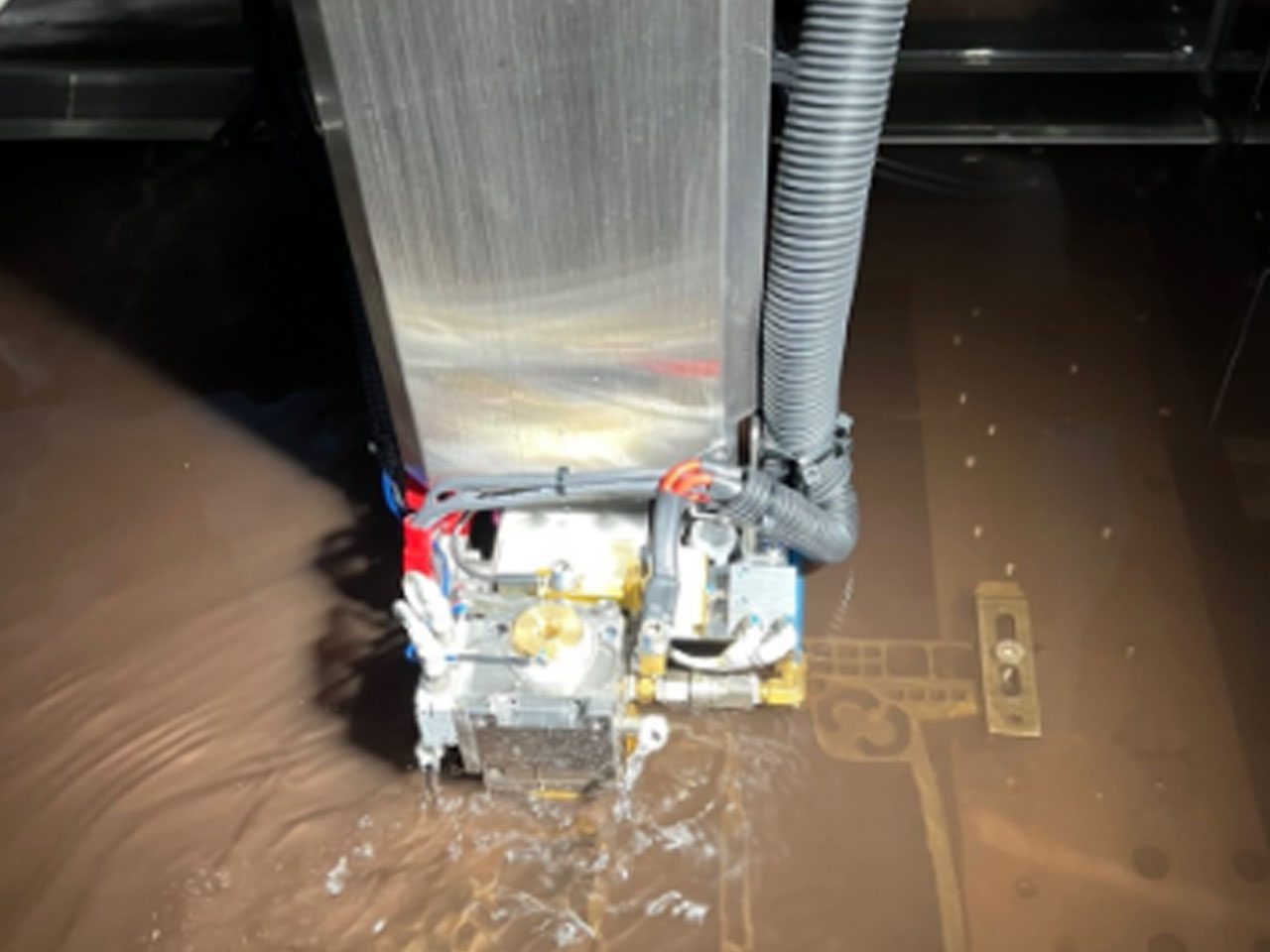

Maualuga saoasaoa uaea tipiina

B

Ogatotonu saoasaoa uaea tipiina

D

Maualalo saoasaoa uaea tipiina (na matou faʻaulufale mai le SIBU Brand Machine mai Iapani)

Faailoga

E iai a matou ituaiga o faʻamasinoga e mafai ai ona faʻamalieina ai au eseese faʻatauga manaʻoga.

Tasi slot faailoga

Fetaomi: 10t-16t

Puleaina Faailoga Faailoga

Fetaomi: 40t-550T

Alualu i luma(Maualuga saoasaoa)Faailoga

PISES: 630T, 550t, 315t (schuler),300t (Aida),160t, 120t, 80t (edec)

Faʻateʻaina o tagata faigaluega

↓

Afrstruct le alualu i luma Schuler meafaigaluega & tekonolosi mai Siamanima Aida, natolo mai Iapani,lea tatou i ai i leafi afialamanuia capinu leve le tumau nei.

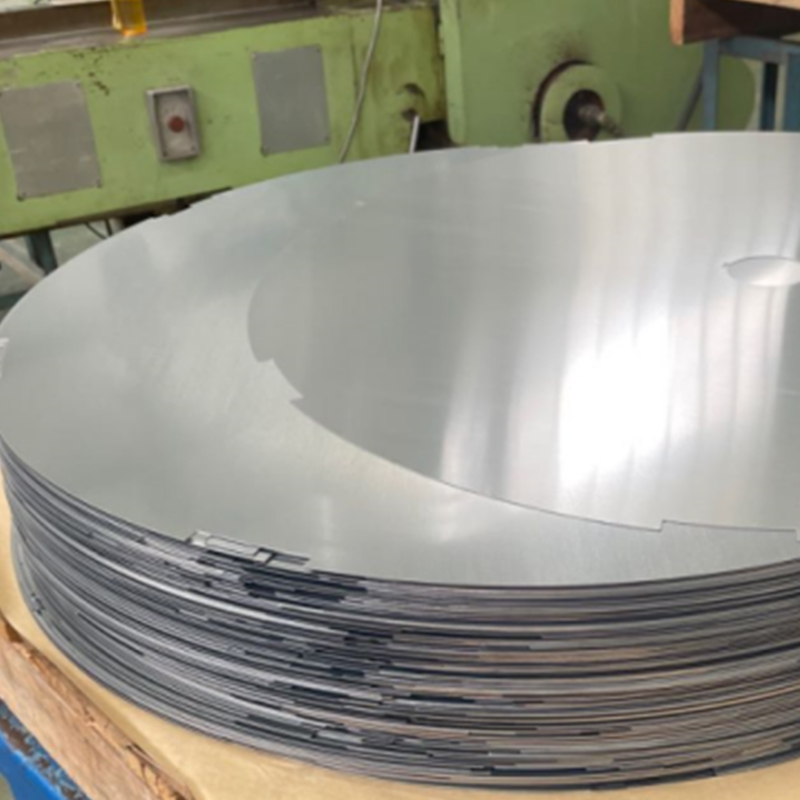

Boachieve Butch Oloa o le 0.1MM o le mafiafia o le sili siliva Steel ma 0.03m mafiafia e le o le le mautonu.

C. O le tasi slot press e mafai ona mafai ona stamp od2000mm max.

Tasi slot faailoga

Meafaigaluega: E leai se mea na tupu

Oti le ie siliva siliva e manaʻomia le manaʻomia, ma o fasi uma o latou taʻitoʻatasi e tapunia i totonu o le foliga manaʻomia. Tasi Slot Stampting o se sili sili ona talafeagai auala mo fuainumera lalagaina ma sili atu fafo sili atu fafo o faʻataʻitaʻiga ma tele o faʻataʻitaʻiga.

Puleaina Faailoga Faailoga

Meafaigaluega: Malaga Maliu

Faʻatau le mea e fetaui ma Ilikin Steel fasi pepa e tusa ai ma le tele o le oloa manaʻomia, faʻaliliu mea i le faʻailoga faʻailoga, ona fai lea o le afi lalagaina. E lua 'aʻai metotia, o le tasi o le faʻaoga lea o lefevle ua afaina e leisi afi poʻo le tele o mea e lelei, ae mafai ona maua le tau tele; O le isi o loʻo faʻaauau pea le fafaga o fasipepa, ma maualuga maualuga. Ioe o le a siakiina le Wance Stock Staff tulaga pe a fai o le tagata faʻatau e fai ai le paoa. E le gata i lea, o le matou kamupani ei ai le pateni i le tuʻufaʻatasia o le gaosia, lea e faʻaitiitia ai le tau o le afi o le alualu i luma.

Alualu i luma le faailoga

Meafaigaluega: O le alualu i luma o oti

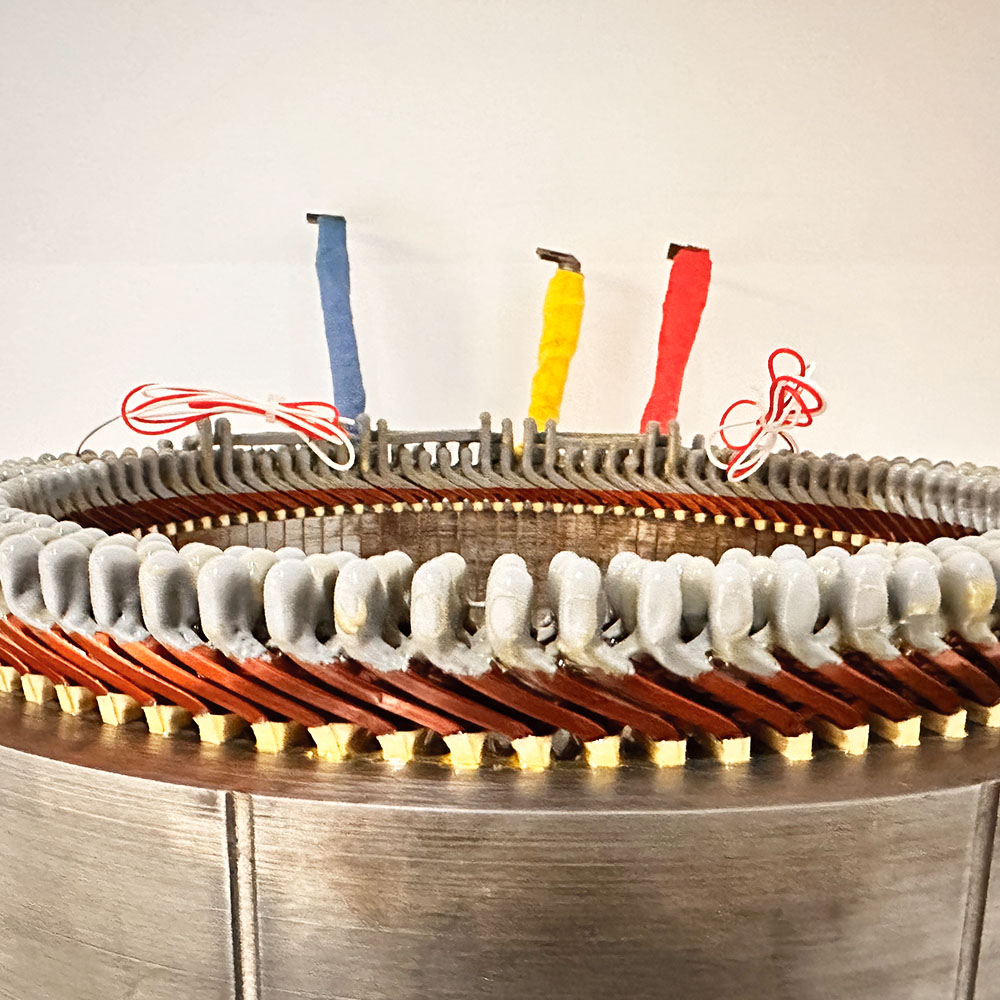

O lenei ituaiga o le ata ua taua foi o le maualuga-saoasaoa stampting suia. Eseese mai le ata o loʻo vaʻaia, naʻo le faʻaaogaina o le loloto o le tino mo le fafagaina, faʻamaeaina le faʻailoga ma le faʻaaogaina o le tagata e fausia ai le fuainumera ma rotor star.

E lua ituaiga o le tagata lava ia o le tagata lava ia. O le tasi o le lapotopoto o le tagata lava ia-interlock mo le tele o le tele o le afi o le afi lauiloa, o le mea lea e iai manaʻoga faʻapitoa. O le faaputuga e le manaʻomia e amata ona oomi faʻalua i le mea e fai ai mea faigaluega. O le isi o le faʻatamala o le tagata lava ia-interlock, lea e manaʻomia ai le maualuga o le faʻamalosi e mautinoa ai

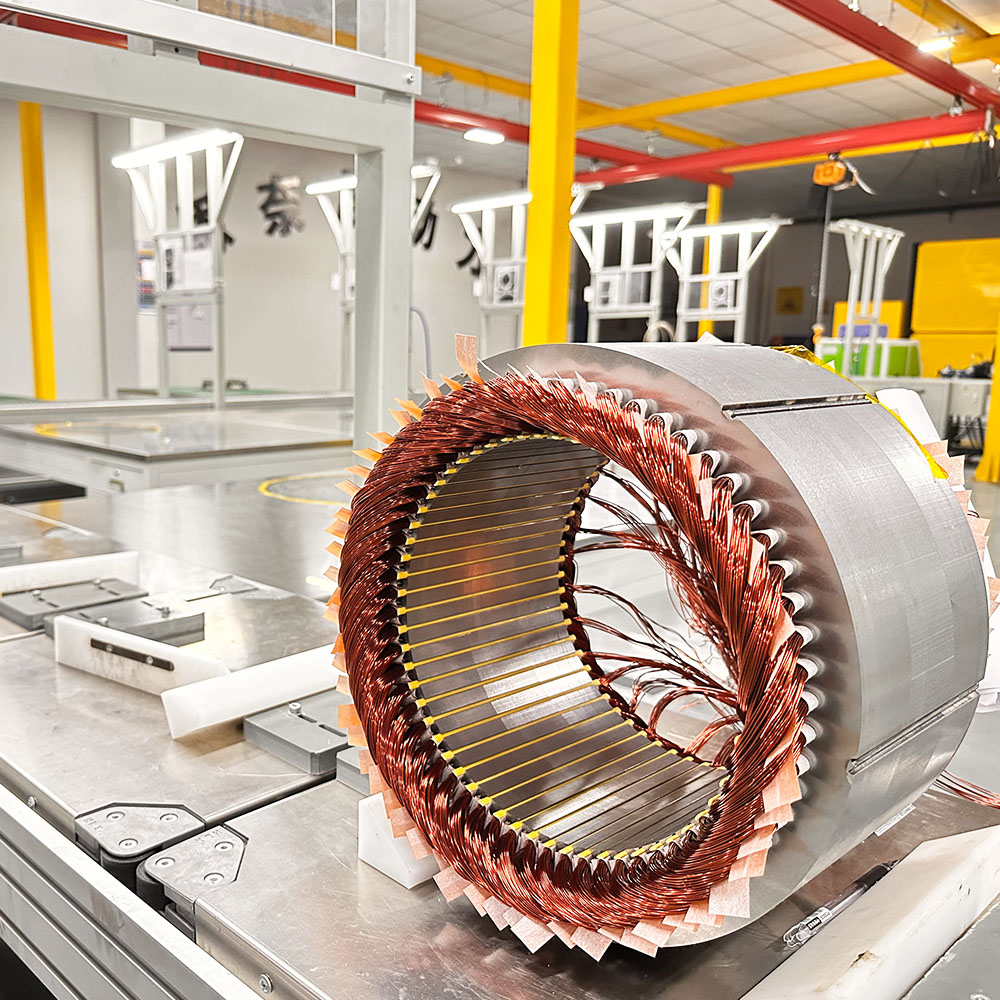

O faʻamaumauga o le fonotaga

Matou te tuʻufaʻatasia uaea ma le pine ma le maina o laʻau laiti uma i le faʻataʻitaʻiga ata ma lapoʻa vaega i le tulaga mulimuli ane, o le o loʻo i ai o le vaega o loʻo i ai i le taimi o loʻo i ai i le o loʻo totogiina le oloa. Faavae 5-50 seti / aso.

Faaputu

O le faatoaga o le a faʻapipiʻiina i meaola e le ruvet, faʻapotopotoga, tatou telē, le faʻapipiʻi, kulimi, bul, buck, o le faʻalapotopotoga fou e maualuga ai.

Ruvet

O le faʻaputuga faʻapipiʻi e masani ona faʻaaogaina mo rotor, e iai le ulu rivet ma mafolafola ruvet.

Toto

O loʻo faʻaaogaina le faʻavasegaina o le faʻaaogaina o le faʻaaogaina

Kelu

O le vali vali i luga o le tasi o le afi afi tutusa ma pipii faatasi.

Faalapotopotoga

Fai le tuʻufaʻatasia o manatu i le taimi o le faʻailoga o le a puʻeina ai le afi o le afi, o le afi o le afi o le afi o latou i o latou tagata. O le soʻotaga e mafai ona faʻatamala pe faataamilo faʻataʻamilomilo. Alualu i luma le faʻaaogaina o le faʻaaogaina uma o le interlock faʻagasologa e sefe le fuainumera ma rotor faaputuga tau ma taimi.

Ia lava

Mea: B35A300-Z / B50A400-Z

O loʻo i ai i luga o le mea o loʻo i luga o le mea, o le a liusuavai ma faʻapipiʻi faʻatasi uma roctor ma fuainumera faʻatasi faʻatasi i le taimi o le faʻamafanafana. O le a le fiafia o le tagata lava ia o le a faia ni oloa lemu ma sili atu le mautu.

Fusi

O Bolt e masani ona faʻaaogaina mo le fuainumera lalagaina ma sili atu fafo sili atu le lautele.

Faʻapipiʻi

Pepa faʻapipiʻi o loʻo faʻaaogaina mo fuainumera lalagaina, e i ai pe skew buckles.

Asiasiga

O a matou suʻega meafaigaluega e aofia ai le poloketi, tolu-tautua, lolomiina malosi mita, penisini, ma le unzel bedes.

O le asiasiga e vaevaeina i le muamua mataupu mataupu, le asiasiga a le tagata lava ia, o le 'aia tatau e siaki ma le mulimuli mulimuli. Tusa lava poʻo le a le metotia faʻailoga o, o ni nai fasi o le afi o le afi o laumua ma ni nai seti o fuainumera ma roots stack e tatau ona afua mai pe a maeʻa le asiasiga.

Afifiina

E tusa ai ma le manaʻoga o tagata, o loʻo teu ai ni faʻailoga ma rootcher ma Rocky pa, o loʻo faʻapipiʻi pusa

A maeʻa le afi afi ma le stargation ma star ma rotor ma rotor ma rotor ma rotor rocks, tatou o le a vavaeina i latou ma le faʻapipiʻiina o le 'aufaamatalaga i fafo atu